A heavy snowfall brings messy roads, snowplows, and salt trucks. But not in Holland, Michigan, due to their 168 miles of tubing beneath the roads and sidewalks. It is the largest snow melt system in the country. Water is heated and sent through the tubing to melt the snow. Roads are snow and salt free. This ‘Snowmelt’ system is made up of about 10.5 acres of heated sidewalks and streets. Streets are clear. There are fewer falls and accidents. The businesses of downtown Holland do well even during the typically slow winter months.

A similar system can be installed by Milmar for your pole barn!

There are several different types of floor installation, but Milmar specializes in concrete slab installation. Even though the process is simple, each step must be done properly or you will have an inefficient heating system. Here are some general guidelines to follow. Be sure to check with the specific manufacturer for installation details and that the job is up to code:

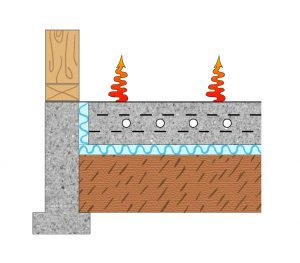

- Have a vapor barrier

This should be a 6-10 mil plastic covering that is laid on top of the compacted earth or sand. Experts recommend Visqueen plastic. (polyethylene plastic) A vapor barrier blocks moisture between the slab and the barrier. As the concrete slab dries, there will not be a moisture problem unless it comes from underneath the slab.

Read here for more details on Vapor Barriers

- Insulate the concrete slab

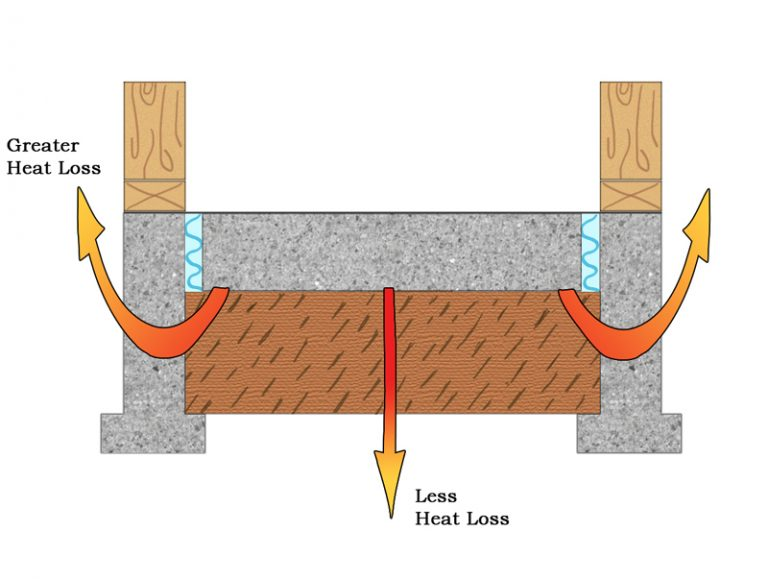

This is an essential step; otherwise your system will not be efficient. Experts recommend extruded or expanded polystyrene (rigid blue or pink board) Foil or bubble sheets are not good insulators for concrete because they have better reflective properties. Since they would be covered by the concrete, there is only a thin layer of insulation. Heat can also escape through the sides of the concrete

*Sides not insulated vs sides fully insulated*

- Lay the radiant floor tubing in the proper pattern

Staple the tubing using specially made Pex staples. Another option is the attach the tubing with zip ties. Pex staples are more expensive, but the zip tie method is more time consuming. There is a product available called Crete-heat. It has built-in grooves to hold the tubing in place. Just snap the tubing in the grooves. Crete-heat also has a built in vapor barrier, plus the pieces simply snap together.

Check out this picture from a recent Milmar build project of all the tubing laid down for a three zone heated floor: (click the picture to view the video of that project)